I’ve been trying to rotate some of my favorite machines recently. I love my Necchi machines so much that I could sew on them forever and never feel like I was missing out on anything (is there such a thing as sewing machine monogamy?) but variety is the spice of life, they say. Also I want to use the others enough to keep them well maintained and to break some of the older ones back in to optimal performance. So I’m revisiting some of my Singer machines.

I currently have two Slantomatic 401s. One of them came to me perfectly tuned, oiled, adjusted. It was the first vintage sewing machines I purchased for myself when I began sewing regularly and the Walmart plastic Brother sewing machine just wasn’t working for me anymore. The first time I sewed with it, I was in love. Compared to the rickety, inconsistent stitch quality of the bargain basement Brother, with its dismal white lump design and utter lack of aesthetic appeal, it was heavenly. The stitches are gorgeous and the feed is so consistent that I can turn my work and sew perfectly over the stitches that came before. *swoon*

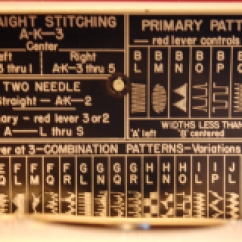

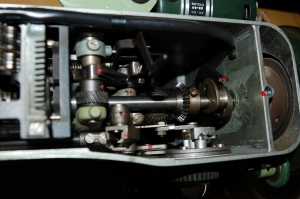

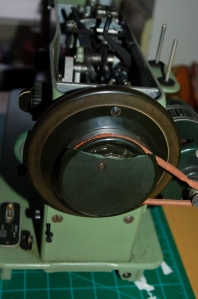

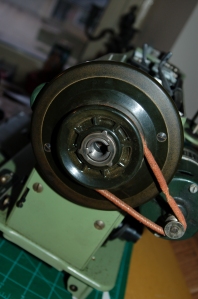

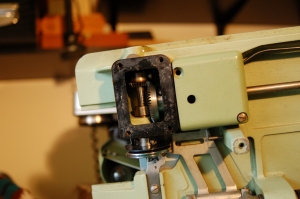

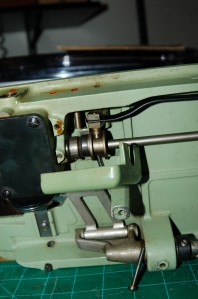

It converted me to a vintage machine enthusiast forever. It’s gear driven, which gives it a feeling of solidity and precision like nothing I’d sewn on before. Internally it’s all metal, save for one part–there is a very large, crucial gear on the handwheel that is actually textolite, a very durable plastic material. Unlike many of the plastic and nylon materials Singer used over the years, it doesn’t seem prone to breaking, thankfully. (For more info, see Old Sewing Gear’s great blog here.) It has zig zag, a blind hem stitch, and three step zig zag stitch built in, as well as a ton of other decorative stitch possibilities. The needle position is adjustable and the needle plate has measurements engraved in it, which is really helpful with seam allowances.

I bought another in awful shape as a clean up project. It was caked in weird greasy gunk externally, which was impossible to get off without alcohol soaked q tips. It was varnished up internally as well, which alcohol works well to clean up–it evaporates quickly enough that it isn’t as much of a problem near wiring as something like WD40 would be (which the jury seems out on using to loosen stuck sewing machines anyway). The camstack and gears that allow for the decorative stitching were bound up as well–I had to use a hair dryer multiple times to allow the warming and cooling of the metal to expand and contract the parts enough to work the oil in and loosen up everything. Now it sticks a bit from time to time, but overall it’s working wonderfully.

So that’s my current go to machine for my foray into sewing with jersey. With a ballpoint needle, it works incredibly well for this purpose. I thought I’d share some photos of mine and some of the technical information I’ve found over the years. (Apologies to the original source of the schematic–although the manual can be found on the Singer website, I’m no longer sure where the schematic is from. And the service manual was made available by Donald of Sewing Dude – his post here. His blog is very informative and very, very funny!)

singer-401-service-manual from Sewing Dude blog